WE BUILD MACHINE VISION AND AI SYSTEMS

SEE. THINK. AUTOMATE

We help industrial companies automate inspection, measurement, and quality control using cameras, sensors, and AI-driven software.

Our systems detect defects, verify dimensions, and improve consistency so manufacturers reduce scrap, avoid downtime, and increase throughput.

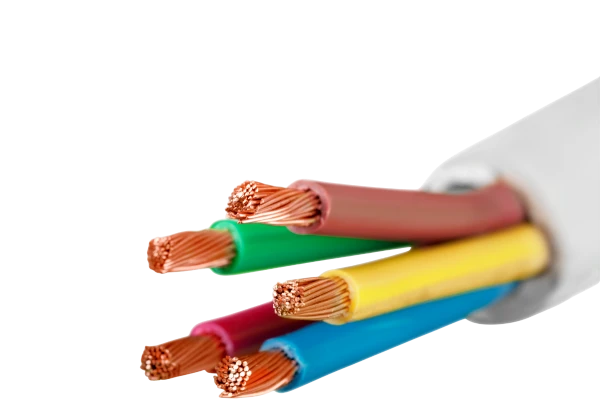

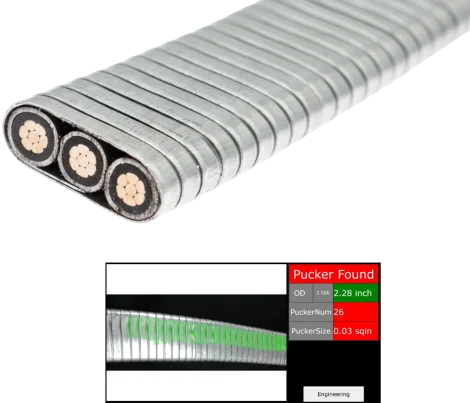

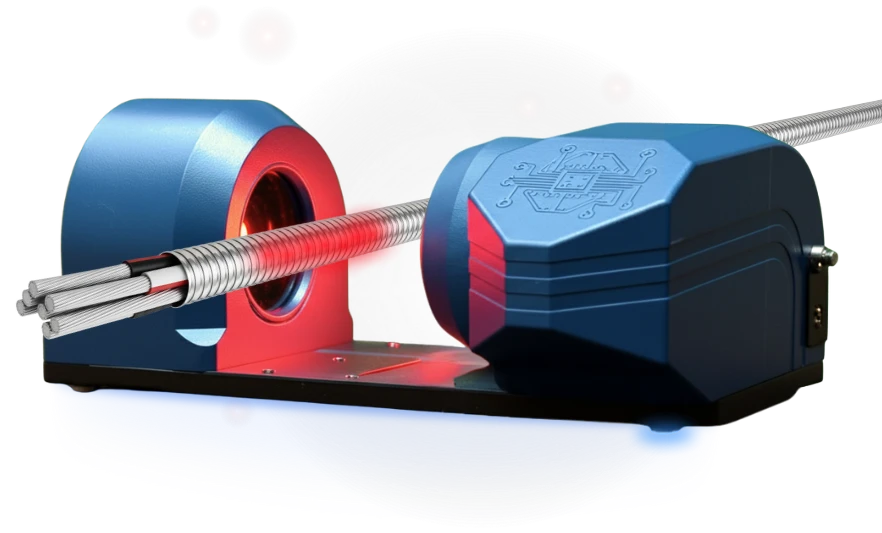

WIRE & CABLE IN MANUFACTURING

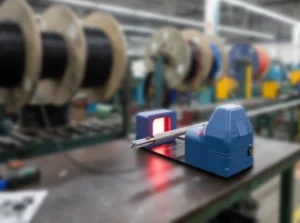

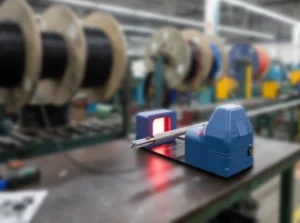

AI-powered inspection systems purpose-built for wire and cable production, from conductor measurement to armor inspection and reel monitoring.

Real-time cable measurement with AI precision for consistent quality and dimensional accuracy.

High-speed vision inspection ensuring perfect tape overlap, pitch control, and defect detection.

Smart inspection that detects armor defects, monitors reels, and enhances safety on the line.

Hybrid AI and vision that exposes hidden armor distortions before they affect production quality.

Improving Accuracy with Machine Vision

Smarter factories start with systems that see, decide, and adapt; all in real time.

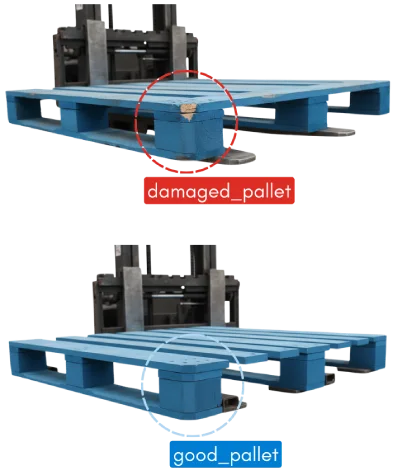

WAREHOUSING AND LOGISTICS

Machine vision systems for pallet inspection and box verification, and thermal anomaly detection.

Real-time visual monitoring for industrial, warehousing, and logistics environments.

Uses thermal vision to detect temperature anomalies, equipment wear, and pallet heat variations in real time.

PACKAGING AND BOTTLING

High-speed AI inspection for bottles, caps, fill levels, and labels.

Detects cap closure, seal integrity, and fill level accuracy on every bottle with instant AI feedback.

Verifies label correctness, text, and QR codes using OCR and AI to eliminate packaging errors.

News

How Machine Vision Is Transforming Wire and Cable Manufacturing

What Is Machine Vision and How CORPEX Uses AI to Enhance It

Welcome to Our Team: Ugur Erdogan, Marketing Manager

How Machine Vision and AI Are Transforming Cable and Wire Manufacturing

News

How Machine Vision Is Transforming Wire and Cable Manufacturing